Aston Resolv4K system build

Custom Optical Vision System for Particle Motion Analysis at Aston University Client: Aston Institute for Membrane Excellence (AIME), Aston UniversityIndustry:

Our client Cogent Breeding Limited, approached us as they needed a replacement solution for a now failing Fraen retrofit UV illumination unit. The client illustrated that UV wavelengths was key to the successful evaluation of their samples, but they needed to continue using the CX23 as it is nicely portable, a familiar system to staff, plus an existing resource.

The design brief in this instance was simple. Add 365nm UV illumination as the primary light source for this microscope. Initially I had some concerns to address.

Firstly, I reached out to an LED manufacturer we work with in Germany and are product distributors for, Starlight Opto Electronics, to see if they were able to custom make something suitable to help achieve the upgrade required.

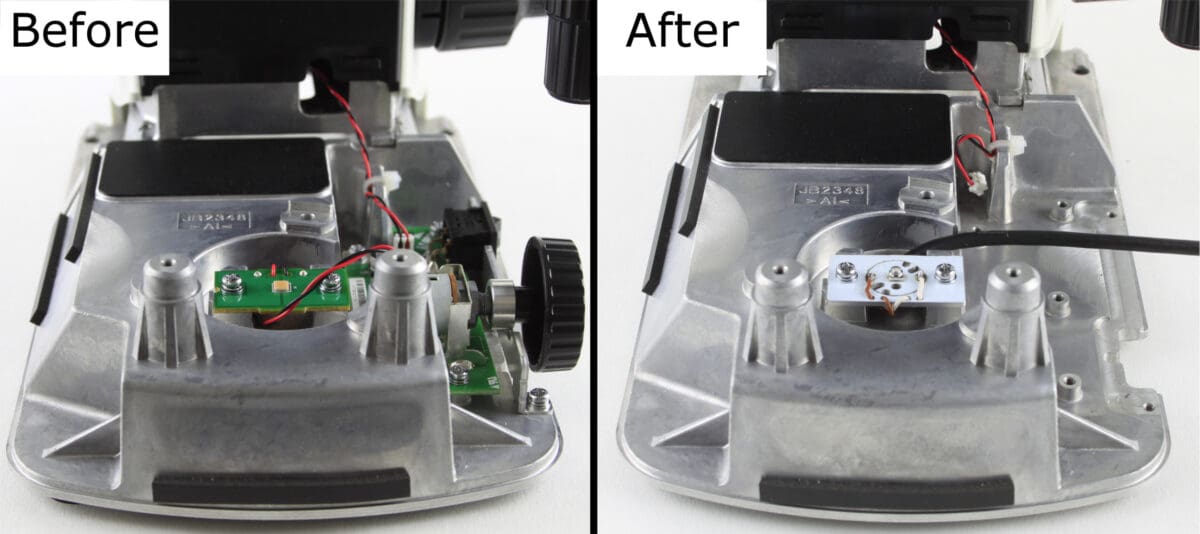

They advised that it was possible to supply me a LED mounted onto a simple PCB to provide the 365nm wavelength required. As I wanted to keep changes to a minimum, I asked that the PCB be made to the same dimensions as the original Olympus part, so that I could mount it identically. This would also mean the optical system inherently aligned with the illumination and would not cause further issues. I provided the manufacturer with drawings and measurement of the original PCB.

Secondly, I needed to protect the users’ eyes from the harmful UV wavelengths, when using the binocular to view the sample. With no intermediary parts in between the objectives and the eyepieces, I needed to find another suitable mounting point for a protective filter. Deconstructing the CX23 I noticed there was some space under the head, just enough to mount a filter. I worked with UQG optics to create a custom-made diameter filter to fit into this space and protect the user.

Thirdly power and control. I wanted to use the original PCB to power the new LED illuminator. However, this was not possible because the UV LED worked differently. Therefore, as a compromise I used the PSU and controller from Starlight to operate the new LED, making the solution part external.

Lastly, the solution configured so far was much less invasive than the Fraen version, though still provided portability as parts were either built in (LED) or small additions (Control box and PSU)

To complete I procured all the new parts and fitted to the microscope. The solution can be seen in the attached images. As usual I oversaw and completed the project from initial quotation all the way to implementation to ensure consistency and accuracy.

If you have specific microscope requirements or need modifications to existing equipment to enhance your optical inspection process, please do consult with us. We take the time to understand your application needs, before providing detailed solution proposals. Contact james@bestscientific.co.uk or email via this website.

Custom Optical Vision System for Particle Motion Analysis at Aston University Client: Aston Institute for Membrane Excellence (AIME), Aston UniversityIndustry:

USB-Powered Portable Ring Light for Field Microscope Illumination Delivering a customised, portable lighting solution for field microscopy, ensuring precision, portability,

Pairing Optics and illumination: Best practices Matching Ring Light Illumination to an Optical System. Explore how matching ring light illumination

Zoom System Configurations for Broad Scale Coverage – Oxford University Case Study Explore how Navitar’s 12x Zoom System was expertly

Optical Vision System Optimisation Case Study: Navitar Resolv4k Lens Series Introduction: Best Scientific proudly announces the successful completion of configuring,

Precision Optics tailored for Success: Optical Vision System Supply and Configuration. Introduction: Discover how Best Scientific seamlessly configured and supplied

New compound microscopes personally delivered and installed to University of Portsmouth. Best Scientific recently completed the supply of 60 compound

New Moticam A series microscope cameras, now available from Best Scientific. Launched in the summer of 2022 this new line